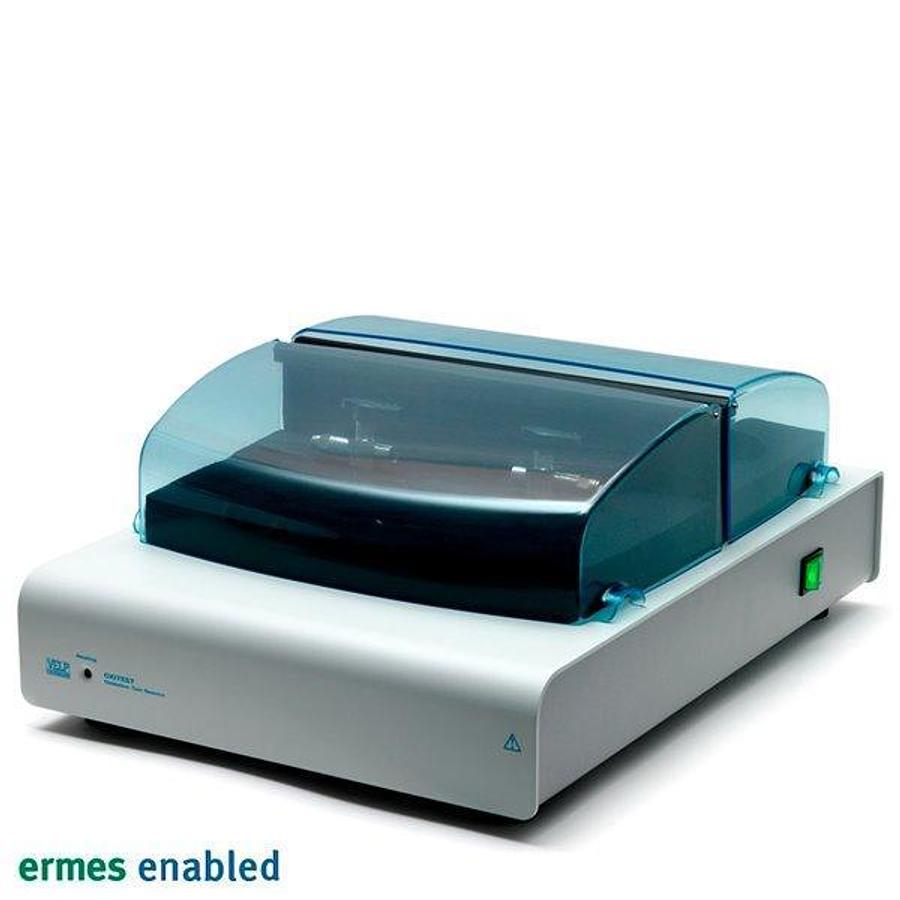

OXITEST Oxidation Stability Reactor

OXITEST Oxidation Stability Reactor

Description

Fats and oils oxidation stability tests for R&D and QC Labs

The oxidation stability tests performed with the OXITEST reactor accelerate the lipid's oxidation process that in normal conditions can last weeks or months and provide fast, accurate and reliable results for Food & Feed, Cosmetic, Pharma and Petrochemical industries.

The OXITEST provides added value information for Quality Control and Research & Development Labs for:

Representative results testing the whole sample

The OXITEST reactor subjects the sample to a high oxidative stress environment in order to evaluate, in a short period of time, the resistance to fat oxidation:

With the OXITEST Method, the stability test is performed directly on the sample as it is solid, liquid or doughy.

The method's key advantage is that the OXITEST ensures representative results without extensive sample preparation.

Other components of the sample matrix such as chemicalor transition metal can promote oxidation andthe use of extracted matter may not be a suitablepredictor of stability.

Downloads:

Specifications

| Manufacturer | Velp Scientifica |

| NUMBER OF OXIDATION CHAMBERS | 2 |

| CAPACITY SINGLE CHAMBER | up to 100 ml |

| PRESSURE RANGE | 0 - 8 bar |

| TEMPERATURE RANGE | from room temp. to 120 °C |

| MAX DEVIATION FROM THE SET TEMPERATURE | ≤ 0.5 °C |

| REPRODUCIBILITY OF SET TEMPERATURE | ≤ ± 0.2 °C |

| INTERFACE | USB |

| CONNECTIVITY | Cloud via LAN or Wi-Fi |

| POWER | 900 W |

| POWER SUPPLY | 115 V / 60 Hz - 230 V / 50-60 Hz |

| WEIGHT | 16.5 Kg (36.3 lb) |

| DIMENSIONS (WXHXD) | 365x190x485 mm (14.6x7.6x19.4 in) |

| OVERPRESSURE | Safety valve |

| OUT-RANGE TEMPERATURE | Visual alarm |

| DAMAGED PROBE | Visual alarm |