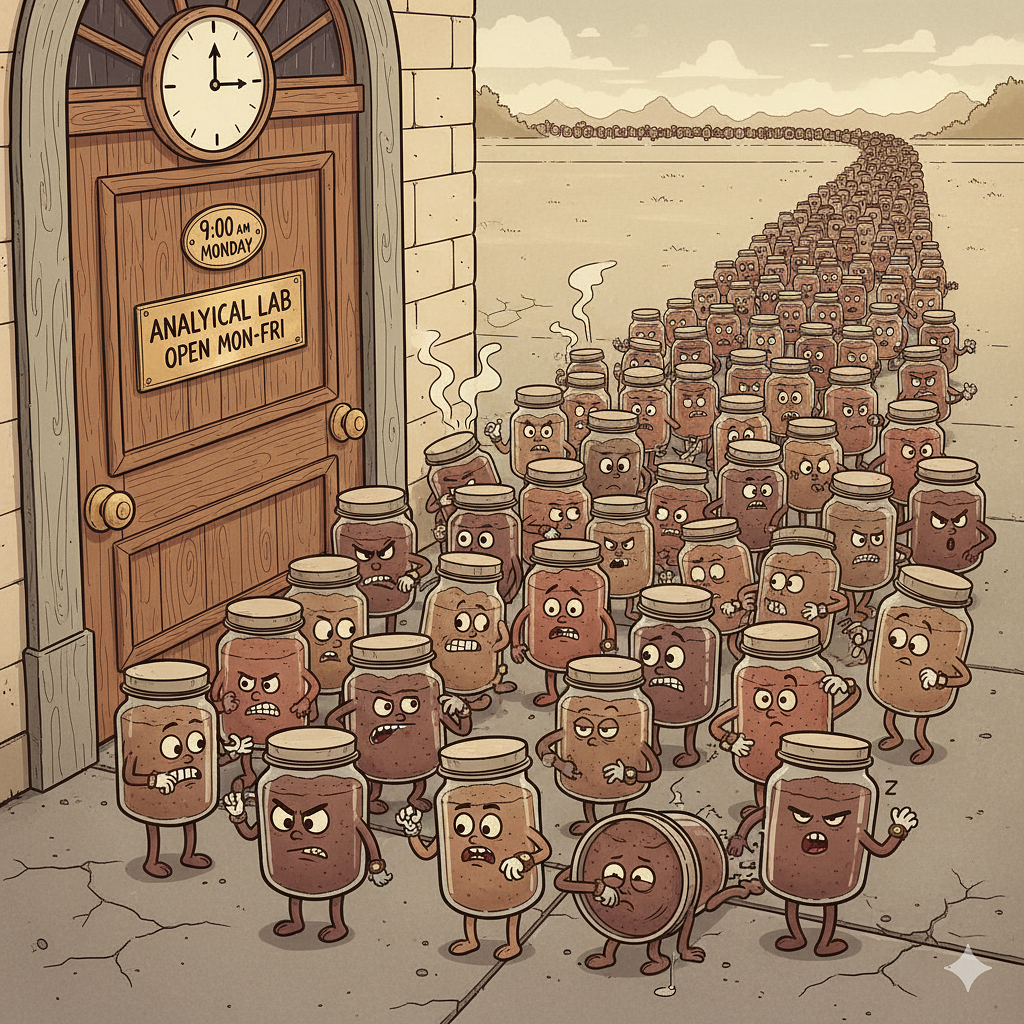

In environmental and geotechnical testing, analytical results are only as reliable as the samples on which they are based. Peak testing seasons raise a familiar challenge:

What happens when sample volumes surge and laboratory capacity is pushed to its limits?

As workloads increase, not all stages of the soil testing workflow are affected equally. In many laboratories, sample preparation, and not analysis, becomes the point where delays, variability, and inefficiencies begin to accumulate.

Pressure points in high-throughput soil testing

A typical soil preparation workflow includes drying, coarse size reduction, fine grinding, and homogenization. While fine grinding often receives the most attention, primary size reduction plays a critical role in stabilizing the entire process. Inadequate or inconsistent coarse reduction leads to longer grinding times, increased wear on fine grinding equipment, and poor homogenization that ultimately compromises representativeness and throughput.

Jaw crushers are well suited to this stage of the workflow because they reduce heterogeneous soil materials to a controlled particle size before fine milling. Designed to process hard, brittle, or mixed materials under continuous use, they support reproducible size reduction without introducing hard metal contamination such as nickel or chromium. With a throughput of up to 300 kg/h, the Retsch BB 250 Jaw Crusher illustrates how modern jaw crushers address these practical laboratory requirements. High crushing capacity, consistent final fineness of below 2 mm, and features such as a front-opening crushing chamber, cyclone-assisted sample recovery, and intuitive controls help keep primary size reduction efficient and predictable.

Fine milling and homogenization for representative samples

Once coarse size reduction is complete, fine milling is used to achieve the particle size and homogeneity required for analytical testing. This step ensures that subsamples accurately represent the bulk material.

Vibratory disc mills are commonly used at this stage due to their high energy input and short grinding times. The Retsch RS 200 Vibratory Disc Mill, for example, enables fast, reproducible fine grinding of hard, brittle, and heterogeneous materials to final fineness values of below 20 µm within 60 to 180 seconds. Moreover, these short, precisely controlled grinding cycles help limit sample heating, reducing variability between samples and maintaining preparation speed during periods of high demand.

Building preparation workflows that scale

Across high-throughput laboratories, effective soil sample preparation workflows share common priorities:

- Preparation steps that keep pace with incoming samples

- Easy cleaning to minimize cross-contamination

- Robust performance across variable materials

- Reduced manual handling to support safe operation

By focusing on controlled primary size reduction and efficient fine milling, laboratories can prevent preparation from becoming a bottleneck and maintain confidence in analytical results, even as testing demands continue to grow.

Contact us to learn more about the power of sample preparation in high-throughput soil testing.