Wastewater analysis plays a critical role in protecting Canada’s water resources, public health, and ecosystems. From municipal wastewater treatment plants to industrial dischargers and environmental laboratories, accurate and timely data underpins regulatory compliance and informed decision-making. With oversight from bodies such as Environment and Climate Change Canada (ECCC) and provincial regulators, laboratories are expected to meet increasingly stringent requirements for nutrient monitoring, traceability, and reporting.

Despite its importance, wastewater analysis remains challenging. Laboratories must balance high sample volumes, complex matrices – all while delivering defensible data that aligns with Canadian regulatory standards. In practice, successful wastewater testing depends on a combination of robust analytical methods, automation, and consistent sample preparation.

The Challenge of Nutrient Monitoring in Complex Matrices

Nutrients such as ammonia, nitrate, nitrite, total nitrogen, and phosphorus are among the most closely regulated parameters in wastewater. Their concentrations directly influence eutrophication, oxygen depletion, and ecosystem health. However, measuring these analytes accurately is far from straightforward.

Wastewater matrices vary widely. Samples may contain suspended solids, organic matter, color interference, or fluctuating concentrations that exceed calibration ranges. Traditional manual methods struggle to handle this variability efficiently. They are labor-intensive, prone to operator variability, and difficult to scale when sample volumes increase — particularly during peak monitoring periods or compliance audits.

At the same time, regulatory limits continue to tighten, demanding lower detection levels, better reproducibility, and fully traceable analytical workflows.

Continuous Flow Analysis: Turning Complexity into Consistency

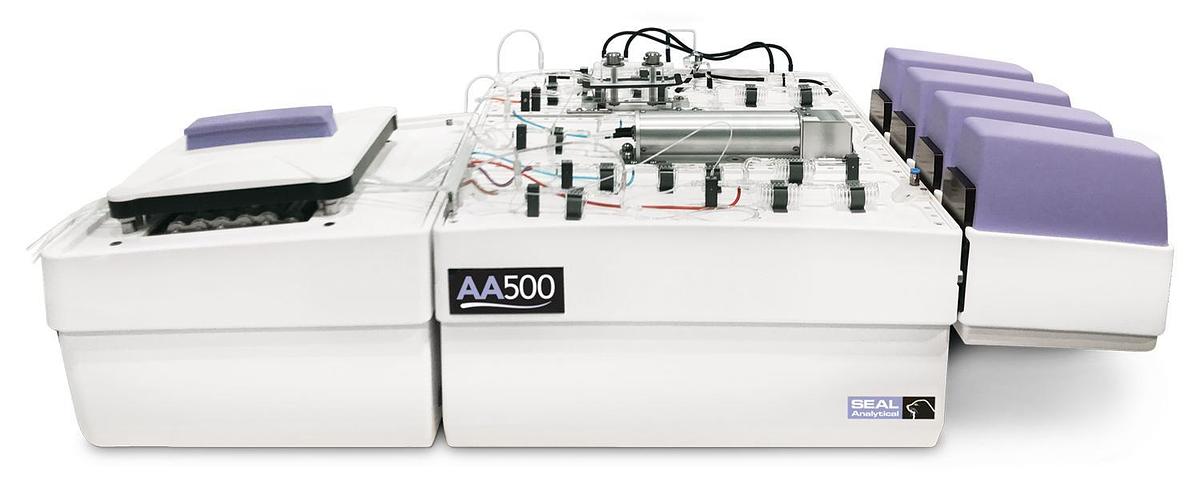

To meet these demands, many Canadian laboratories rely on segmented continuous flow analysis (SFA) – a proven technology widely accepted in environmental testing. Continuous flow analyzers such as the SEAL Analytical AA500 are designed to deliver consistent, high-quality results even in complex wastewater matrices.

By introducing air segments between samples, segmented flow technology prevents carryover, ensures thorough mixing, and allows chemical reactions to proceed under tightly controlled conditions. This approach delivers consistent peak shapes, excellent repeatability, and reliable low-level detection — even when sample composition varies significantly.

The AA500 platform enables laboratories to run multiple nutrient parameters simultaneously, achieving high sample throughput without sacrificing data quality. Automated dilution of over-range samples ensures that unexpected concentration spikes do not interrupt analytical runs or require re-analysis, further improving efficiency and workflow continuity.

Automation as a Solution to Labor and Error

Manual handling remains one of the largest sources of error and inefficiency in wastewater analysis. Tasks such as reagent addition, digestion, distillation, calibration, and shutdown routines consume valuable technician time and introduce opportunities for inconsistency.

Modern continuous flow analyzers address this challenge through end-to-end automation. Automated startup and shutdown sequences, inline digestion and distillation modules, and software-controlled calibration routines reduce hands-on involvement while improving reproducibility.

For laboratories operating with limited staff or extended run times, true walk-away operation is more than a convenience – it is a necessity. Automation allows skilled analysts to focus on data interpretation, troubleshooting, and method development rather than repetitive manual tasks.

Achieving regulatory compliance is not only about meeting numerical limits; it is about confidence in the data. Laboratories must demonstrate that results are accurate, reproducible, and traceable – particularly when data is used for permitting, enforcement, or environmental reporting.

Advanced optical systems, such as high-resolution LED photometers and inert glass manifolds, enhance analytical sensitivity and long-term stability. Optional modules like inline gas diffusion, dialysis, and UV digestion further reduce matrix interference, allowing laboratories to meet stringent detection requirements without complex external sample preparation.

The result is data that withstands regulatory scrutiny while remaining practical for routine operation.

Sample Preparation: The Often Overlooked Foundation

While analytical instruments receive much of the attention, sample preparation plays an equally critical role in wastewater analysis. Poorly mixed or inconsistently treated samples can undermine even the most advanced analyzer.

Flocculation and jar testing are essential for understanding and optimizing treatment chemistry – particularly when evaluating coagulants, polymers, or process changes. Without controlled and repeatable mixing conditions, results can vary significantly between operators or test runs.

The VELP FC-S Series Flocculators address this challenge by providing precise, independent control of stirring speed and timing across multiple positions. This allows laboratories to simulate different treatment scenarios side by side, generating reliable, reproducible data to guide process decisions. Consistent sample conditioning upstream ultimately translates into more representative analytical results downstream.

Data Integrity and Workflow Integration

As Canadian wastewater monitoring programs expand, laboratories must manage increasing volumes of data while maintaining traceability and compliance. Integrated software platforms support centralized control of analytical runs, visualization of results, and standardized reporting formats aligned with regulatory expectations.

Effective wastewater analysis requires more than a single instrument or method. It demands a holistic approach that integrates sample preparation, automated analysis, and data integrity – all tailored to Canadian regulatory and operational realities.

Continuous flow analyzers provide the accuracy, throughput, and reliability needed for nutrient monitoring across diverse wastewater matrices. Laboratory flocculators ensure consistent sample conditioning and meaningful process insights. Together, they help Canadian laboratories move beyond reactive testing toward proactive environmental stewardship.