Stability and self-life are at the heart of product quality. Whether in food, cosmetics, pharmaceuticals, or specialty materials, understanding how long a product stays fresh, safe, and functional shapes everything from formulation decisions to packaging design and production workflows. Despite its importance, shelf-life determination is often misunderstood or oversimplified. In reality, stability is influenced by a network of chemical, physical, and environmental factors – and two analytical tools play a central role in understanding it: oxidative stability testing and modified-atmosphere gas analysis.

The Challenge of Oxidation in Modern Formulation

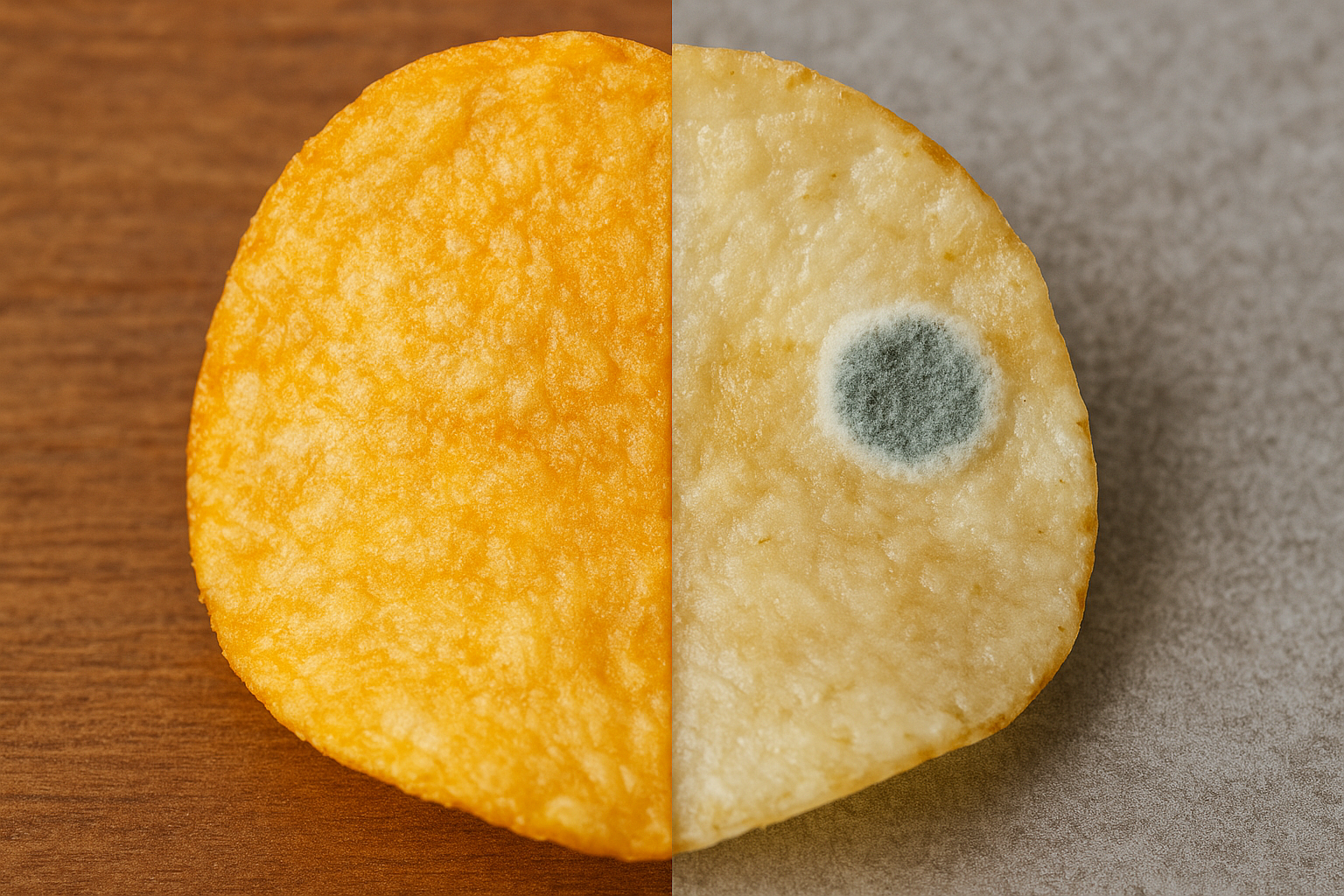

Many products contain lipids, oils, emulsions, or other oxidation-sensitive ingredients. Once exposed to oxygen, these components undergo chemical reactions that lead to rancidity, off-flavours, nutrient loss, colour changes, and in some cases the formation of harmful compounds. The difficulty is that oxidation is slow. Under normal storage conditions, it may take months before deterioration becomes noticeable.

This is where accelerated testing becomes indispensable.

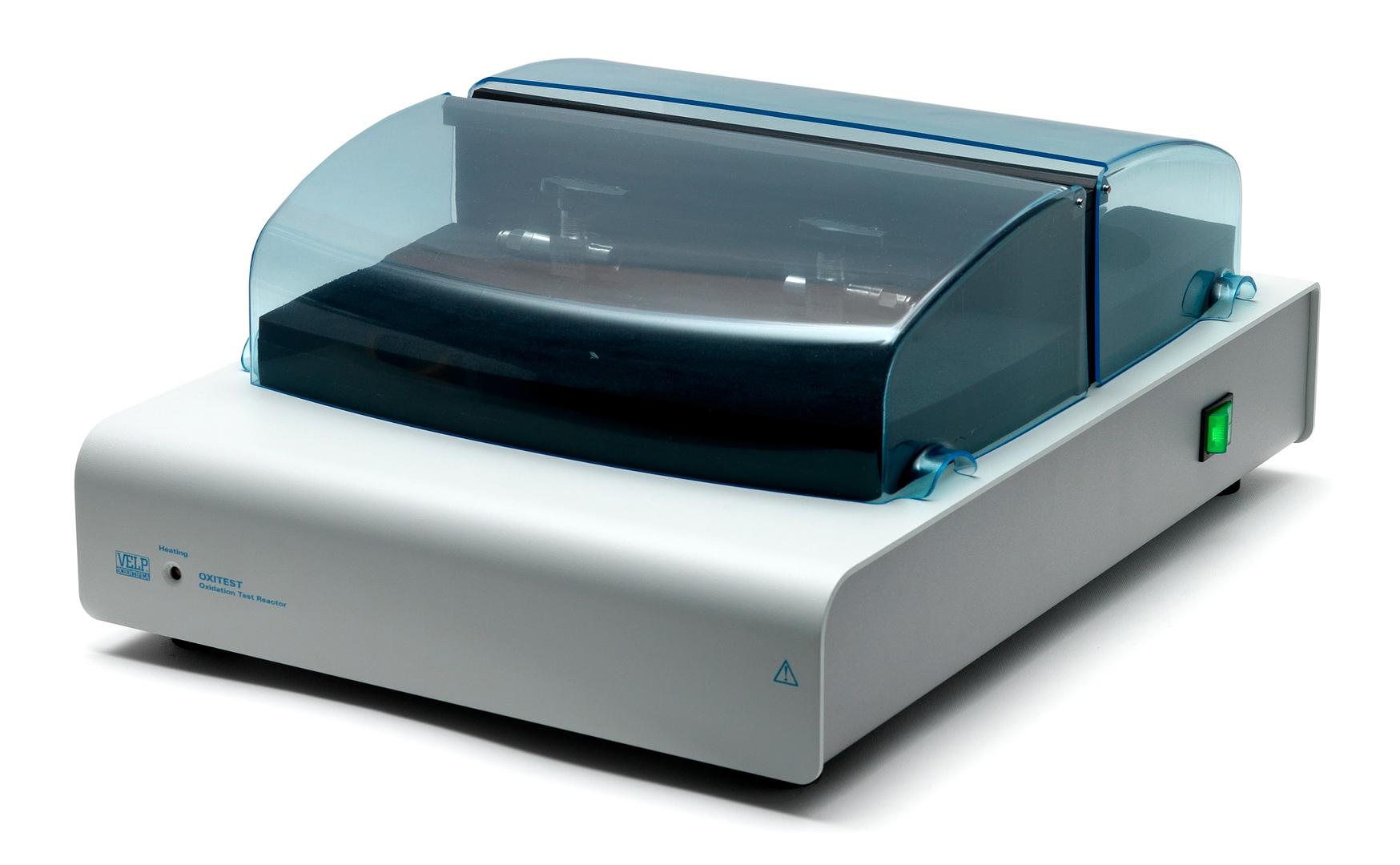

The VELP OXITEST Oxidation Stability Reactor is designed to simulate long-term oxidative stress in a controlled, accelerated manner. By applying high oxygen pressure (up to 6 bar) and elevated temperature, it forces oxidation reactions to occur faster while still following the natural mechanisms of degradation. This enables researchers to study the onset of oxidation in hours instead of weeks.

The test produces a key parameter: the Induction Period (IP). This is the moment when oxidation sharply increases, indicated by a sudden drop in oxygen pressure inside the chamber. A longer IP corresponds to greater resistance to oxidation – and, in practice, a longer potential shelf life. Because OXITEST analyzes whole, unextracted samples, it captures the full influence of matrix effects, antioxidants, contaminants, and trace metals on oxidative behavior.

For industries working with oils, nuts, snacks, bakery products, creams, lotions, pet food, or functional ingredients, oxidative stability is one of the biggest factors that dictates how long a product remains acceptable to consumers.

One of the strengths of modern oxidation testing lies in the ability to control and analyze large amounts of stability data. Software such as OxiSoft™ enables users to run multiple reactors simultaneously, visualize oxidation curves, compare formulations, and build predictive models. Cloud connectivity through platforms like VELP Ermes takes this further: remote monitoring, automatic alerts, and data storage help labs maintain continuous oversight of long-duration tests.

This level of insight streamlines several stages of development:

- Formulation decisions: Compare ingredient suppliers, antioxidant strategies, or recipe changes.

- Process optimization: Evaluate roasting, heating, drying, or preparation steps that influence lipid degradation.

- Packaging evaluation: Study how different materials or sealing processes affect oxidation rates.

- Shelf-life modeling: Generate reliable, reproducible data to support label claims.

As product cycles become shorter and consumer expectations rise, rapid access to stability information becomes not just convenient, but essential.

Packaging: The Other Half of the Shelf-Life Equation

Even the most oxidation-resistant formulation can deteriorate quickly if packaged in a suboptimal environment. That’s why modified atmosphere packaging (MAP) is used in the food sectors. MAP relies on carefully controlled ratios of gases – typically oxygen, carbon dioxide, and nitrogen – to slow spoilage, inhibit microbial growth, and preserve texture, flavour, or potency.

Verifying these gas levels is where A. KRÜSS MAT series gas analysers come into play. These instruments measure the internal atmosphere of packaged products with high accuracy, helping ensure that the intended protective environment is actually maintained.

The product family includes:

- MAT1100, which measures oxygen using an electrochemical sensor for quick, routine checks.

- MAT1200, which measures both oxygen

- and carbon dioxide using EC and nondispersive infrared (NDIR) sensors.

- MAT1400 and MAT1500, which use highly stable zirconium dioxide (ZrO₂) technology for drift-free oxygen analysis, with the MAT1500 also incorporating NDIR CO₂ measurement.

These instruments allow manufacturers to validate their packaging process, troubleshoot leaks, verify mixing accuracy in gas flush systems, and monitor shelf-life studies under real-world conditions. Because MAP often determines how long a product can remain attractive on the shelf, gas analysis is a critical tool for controlling quality and reducing waste.

A Holistic Approach to Stability

Oxidative stability testing and gas analysis complement each other. One helps you understand how a formulation behaves under stress; the other ensures the protective environment around that product remains intact. Together, they create a comprehensive picture of stability across the entire product’s lifecycle.

In a market that demands transparency, efficiency, and long-lasting products, understanding stability is no longer optional. Accelerated oxidation testing and MAP gas analysis give manufacturers a fast, science-based way to make better decisions – whether they’re refining formulations, building packaging systems, or verifying quality at scale. Together, these tools unlock a clearer, data-driven path to reliable shelf-life performance.