Liposomes have become a cornerstone in modern formulation science – from targeted drug delivery and vaccines to cosmetics and nutraceuticals. Their ability to encapsulate both hydrophilic and hydrophobic ingredients makes them uniquely versatile. Yet, anyone who has tried to make liposomes knows how complex it can be to achieve consistent size, uniformity, and stability. The key challenges lie in how liposomes are formed and how their size is measured. Without precise control and reliable analysis, reproducibility and performance suffer – a major concern for any lab or production facility moving from research to scale-up.

The challenge of reliable liposome formation

Traditional methods, such as thin-film hydration or ethanol injection, are widely used at the bench scale because they are simple and inexpensive. Lipids are dissolved in organic solvent or dried into a film, then hydrated in an aqueous buffer to form multilamellar vesicles. However, these bulk processes are inherently inconsistent. They often produce large, heterogeneous vesicles that require further size reduction by sonication or extrusion – additional steps that add variability and limit scalability. For researchers, this can mean repeating the same process multiple times to reach acceptable size ranges, consuming valuable time and materials.

For scale-up or GMP manufacturing, those inconsistencies translate directly into risk. Each batch may behave differently in stability tests or filtration, and even small shifts in size distribution can affect the encapsulation efficiency or drug release profile. This unpredictability creates a bottleneck between development and production, especially when regulatory standards require tight control of critical quality attributes.

Turning to high-shear and microfluidic processing

To overcome those limitations, processors like Microfluidizer® technology have become the preferred solution for producing uniform liposomes. Unlike traditional mechanical or manual size-reduction steps, high-shear fluid processing delivers controlled energy directly to the lipids, breaking down large multilamellar vesicles into small, unilamellar ones with narrow size distributions. The process can reliably produce liposomes in the 50–150 nm range, often with a polydispersity index (PDI) below 0.1 – well within the threshold for pharmaceutical applications.

Compared to solvent injection or microfluidic “bottom-up” techniques, high-shear processing also offers higher throughput and higher lipid concentrations. This is a critical advantage for teams moving beyond small-scale formulation studies. Rather than producing very dilute dispersions that require solvent removal and reconcentration, the Microfluidizer process yields ready-to-formulate liposomes at process-scale volumes. In short, it transforms what used to be a batch-to-batch headache into a repeatable, scalable process.

Why particle size analysis is often the hidden bottleneck

Even with an optimized manufacturing method, understanding what you’ve made – and ensuring it stays stable – depends on reliable particle size analysis. Here, many users face another challenge: liposome suspensions are highly concentrated, often opaque, and sensitive to dilution. Conventional particle sizing instruments may require significant dilution to obtain a readable signal, but the dilution itself can alter the sample’s equilibrium, changing the measured size or stability.

Dynamic light scattering (DLS) is the most common technique for measuring liposomes, yet not all DLS systems are designed for high-concentration samples. As the concentration rises, multiple scattering and light attenuation distort results, leading to underestimation of size or artificially narrow distributions. The result is uncertainty – a major frustration when validating process consistency or troubleshooting formulation changes.

Measuring liposomes without dilution – a practical breakthrough

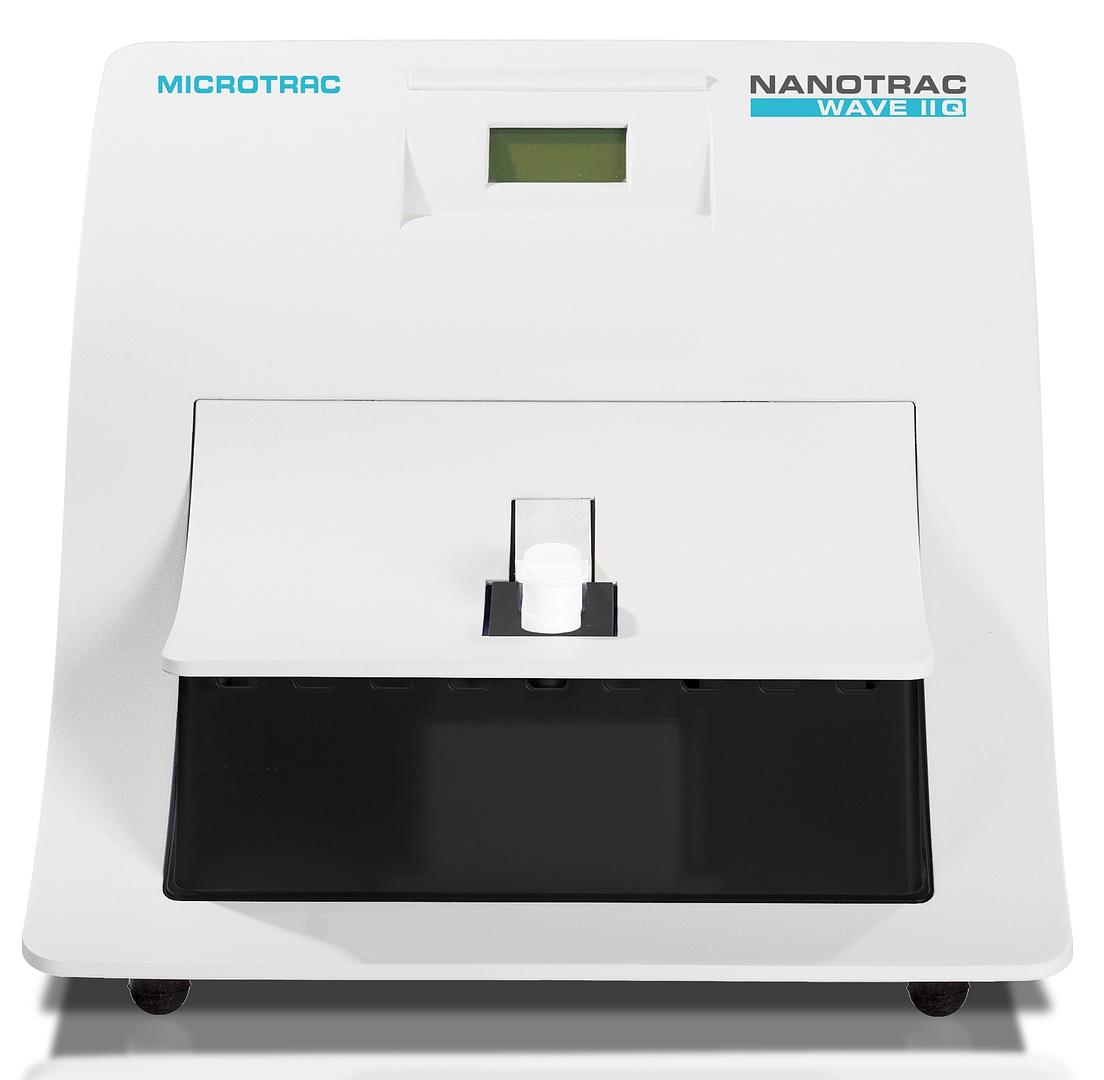

Recent advances in particle sizing technology now allow accurate measurement of concentrated liposome and micelle suspensions without dilution. Systems such as Microtrac’s NANOTRAC WAVE II Q use enhanced backscattering optics and short pathlength design to measure samples at up to 40 % solids, maintaining the sample’s native state. This capability eliminates one of the biggest sources of error in liposome characterization.

For formulators, the benefit is immediate. Measurements can be made directly on production samples, ensuring true representation of size and distribution. Changes in vesicle integrity, aggregation, or lamellarity are detected quickly and reliably. Stability studies become more meaningful because measurements reflect the actual formulation, not a diluted approximation. And for quality control teams, at-line measurement of undiluted samples simplifies workflows and reduces testing variability.

From pain points to process confidence

The combination of high-shear liposome production and high-concentration particle size analysis addresses the two main pain points in liposome development: reproducibility and reliability. Together, they provide a seamless workflow – from formulation through scale-up and quality control.

For researchers, this means faster optimization and less trial-and-error. For production teams, it means consistent batches and predictable performance. And for regulatory or quality assurance professionals, it means verifiable, traceable data on one of the most critical physical attributes: particle size.

Building confidence through the right tools

As demand for liposomal formulations grows, so does the need for practical solutions that bridge R&D and manufacturing. Partnering with suppliers who can offer both process and analytical technologies – along with application expertise – helps customers simplify this journey. Whether developing a novel therapeutic, optimizing a cosmetic formulation, or scaling up nutraceutical production, combining Microfluidizer® processors with advanced particle size analyzers like the NANOTRAC WAVE II Q enables users to move from complexity to confidence.

By focusing on process control and accurate measurement, laboratories and manufacturers alike can transform liposome preparation from an unpredictable experiment into a reliable, scalable process – one that consistently delivers the performance these versatile vesicles promise.